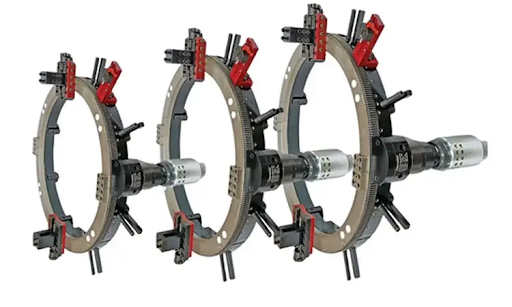

Cold Pipe Cutter Machine

Innovation has always been the primary factor behind increased productivity and safety in the field of industrial pipe cutting. A turning point in the industry was reached with the release of the Cold Pipe Cutter Machine, which provided innovative solutions to pipe cutting problems. We will examine the various benefits of this cutting-edge technology in this article, as well as the rise in the number of trustworthy pipe cold cutting machine suppliers meeting the demands of global industries.

Advantages of Cold Pipe Cutter Machines:

- Precision and Consistency:

Due to the sophisticated cutting mechanisms used in cold pipe cutter machines, cuts are consistently exact. The automated procedure makes sure that cuts are consistent, reducing mistakes and increasing the overall effectiveness of pipe cutting jobs. This accuracy is vital for producing dependable and leak-proof couplings, which are required in many industrial applications.

- Enhanced Safety Measures:

Any industrial activity must prioritise safety, and the cold pipe cutting machine shines in this area. These devices greatly lower the chance of accidents and injuries in comparison to traditional approaches, which call for a lot of human interaction. Thanks to the remote control operation of these equipment, operators may now operate from a secure distance. The machine’s self-locking function also assures stability when cutting, reducing the possibility of unforeseen pipe movements.

- Time and Cost Savings:

The cold pipe cutting machine is fully aware that time is money. With the help of this cutting-edge technology, cutting pipes takes much less time, increasing production. The efficient and automated process also lowers labour expenses, enabling businesses to devote resources to other important activities. Additionally, the exact cuts avoid material waste, which further reduces costs.

- Versatility and Adaptability:

The adaptability of the cold pipe cutting machine is one of its most appealing features. These devices are perfect for a variety of industrial applications since they can handle different pipe types and sizes. The cold pipe cutter machine offers consistent outcomes whether cutting steel, copper, or even plastic pipes. The machines can also adapt to cutting pipes in constrained or small places, making them essential equipment for a variety of difficult jobs.

The Rise of Pipe Cold Cutting Machine Suppliers:

A new generation of pipe cold cutting machine vendors has developed, giving the industry a wide range of alternatives as the need for cold pipe cutter machines rises. These companies provide state-of-the-art equipment that meets the changing demands of contemporary industry. Customers may now pick from a variety of models, each with distinctive characteristics catered to certain cutting needs. The market’s robust competition encourages ongoing innovation and pushes the limits of what these machines are capable of.

Conclusion:

Undoubtedly, the industrial pipework environment has changed as a result of the development of cold pipe cutter equipment. These machines’ accuracy, safety, ability to save time and money, and adaptability have made pipe cutting an effective and dependable procedure. Industries now have access to a variety of alternatives to meet their unique demands thanks to the competition among pipe cold cutting machine vendors to offer the newest technology.

The development of cold pipe cutting machines is expected to continue as time goes on. These machines are expected to reach new heights as a result of developments in robotics, artificial intelligence, and automation, offering even more effective, secure, and flexible solutions for industrial pipe cutting. As more businesses adopt this cutting-edge technology, their operations throughout the globe are undergoing significant advancements that are boosting productivity and raising safety standards. The cold pipe cutter machine has transformed how we deal with pipes in the twenty-first century, whether it is in the oil and gas, construction, or industrial industries.